Aluminum Sand Foundry

Aluminum Sand Foundry & Machining Works

Chuo Yii Enterprise Co. is committed to continuous improvement and strick process control. With over 30 years of manufacturing experience, Chuo Yii has successfully completed numerous domestic and international OEM aluminum sand casting projects. Combining the advantages of sand mold casting and the advanced CNC machining capabilities, Chuo Yii elevates the quality of aluminum alloy casting to new heights. Chuo Yii has become an indispensable leader in Taiwan’s aluminum sand casting industry.

Chuo Yii Core Advantages in Aluminum Sand Casting

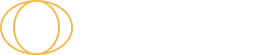

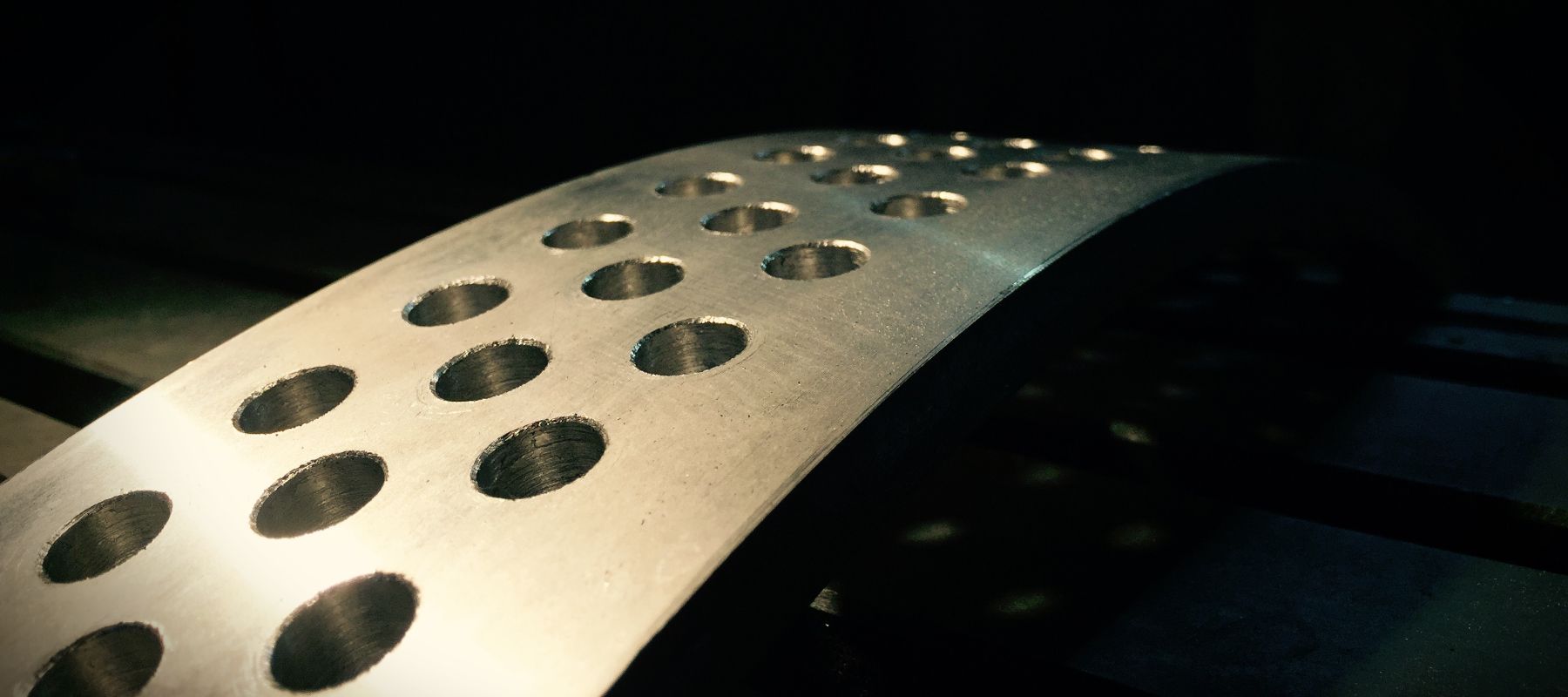

Chuo Yii's facilities can handle single castings up to 3000kg in weight and 2600 × 1300 x 2500 (cm) in size, enabling us to take on projects that range from medium-sized industrial parts to extra-large, specialized components. Industries served include plastic machinery (e.g., blown-film air rings), marine components, agricultural machinery parts, construction equipment, robotic arm components, textile machinery parts, automotive and motorcycle parts, hydraulic components, and even defense and aerospace applications such as low-orbit satellites and military radar systems.

Expert Material Selection

Chuo Yii guides customers to choose the right alloy for each application, considering mechanical properties such as tensile strength, hardness, corrosion resistance, and casting performance. Commonly used alloys include A356, AC4C, 6061 and other industry-grade materials suited for various environmental and structural demands.

Significant Cost Benefits

Compared to large-scale aluminum forging, Chuo Yii's sand casting process can achieve substantial savings. For example, a large automatic air ring housing and its accessories, when produced by forging and machining, can cost over ten times more than our sand casting equivalent. While forging may yield higher density and strength, sand casting offers the ideal balance of cost, complexity, and adequate performance—especially for large or intricately shaped parts where extreme strength is not essential, such as pump bodies, valve housings, and casings.

High Design Flexibility

Sand casting allows greater shape freedom due to the excellent mold plasticity of sand and the creative use of sand cores. This makes it possible to realize complex geometries, intricate internal passages, and designs that would be challenging or uneconomical to achieve by forging or machining alone.

Capability for Large-Scale and Specialized Production

Chuo Yii's process is well-suited for small-batch, multi-variety production while accommodating oversized castings beyond the physical limits of most machining centers. Rapid cooling and solidification shorten cycle times, allowing us to produce multiple castings in a single run and respond quickly to custom orders.

Superior Sand Casting Technology Reduces Defect Rate

Aluminum sand casting often faces challenges such as porosity and surface defects that compromise quality and strength. Chuo Yii has developed a proprietary sand casting process that overcomes these bottlenecks, reducing porosity defects by up to 90%. The result is smoother, denser, and more stable castings with a controlled defect rate of less than 5%. This significantly minimizes the need for secondary machining or manual rework.

Chuo Yii, Your Trusted Partner in Aluminum Sand Casting

By combining material know-how, cost efficiency, design flexibility, large-scale production capacity, and advanced finishing techniques, Chuo Yii Enterprise Co. stands as one of Taiwan’s leading and most reliable partners in the aluminum sand casting industry. Our mission is to provide every client with castings that deliver the right performance, at the right cost, with the right quality—every time.

Features

- Customized object from small to giant size

- Fine surface treatment, glossy and flatness

- Skillful pre-treatment of Aluminum alloy allowing sand casting works more durable and high strength

- By Furan resin and soft sand casting tools

- Giant size objects such as: agricultural film air ring up to 3200mm o.d.; other object such as robot arm, industrial machine parts and marine parts

- Related Products

Mulch film Gaint Air ring

CYG-6

CYG-6 air ring is applied in general purposes blown film such as, making of shopping bag, grocery bags, garbage bag and so on. While, to most of the cases...

DetailsFine Tunning Air ring

AREO-3

Main function of the adjustable air ring AREO-3 is to rectify film thickness variation due to precision problem of die head. Fine tuning is available...

DetailsAdjustable Stabilizing Ring

Iris ring

Adjustable design of the size control knob with lock-on function.

DetailsHDPE Central column set

Central column

In HDPE blown film, worker always suffered from unstable HDPE bubble drawn up. It may be due to imprecision die head or material itself . However, owing...

Details- Showcase Video