Company Profile

Aluminum Sand Foundry OEM & Air rings

Chuo Yii specializes in aluminum sand casting, supplying a wide range of industrial OEM aluminum precision castings and machining services for both domestic and overseas markets. With over 30 years of expertise, Chuo Yii has further advanced into in-house production of high-performance air rings for plastic blown film machinery. From pattern making, aluminum sand casting, casting inspection, machining to product assembly— all are completed in Chuo Yii’s own facility.

From Automotive to Aerospace: Aluminum Sand Casting Expertise

Aluminum sand castings include auto motive and motorcycle parts, mechanical components such as robot arms, marine components, textile machine parts, EDM bed, and Low Earth Orbit Satellite basement, or military and defense equipment (Radar basement) and etc. The Aluminum sand casting materials cover with various Aluminum alloys such as A356, AC4C, 6061 and etc. The production capacity of the largest aluminum castings are up to 3,000 kg in weight and within dimensions of 2.6x1.3x2.5(meters).

Air Ring Production Center

For plastic blown film extrusion: Owing to yearly experience and full capacity to produce Air Rings, Chuo Yii Enterprise Co. later set up machining and manufacturing center, where particularly aims at manufacturing of Air Ring and the related components such as Die Heads and other accessories for plastic blown film extrusion. The manufacturing concept has been combined with principle of Venturi Effect to manufacture all Air rings and Die head, from mono layer blown film to multi-layer film; such as shopping bag film, barrier film and lamination film. Chuo Yii act to provide machine builders the best solution to various blown films challenges. CY air rings and die heads are working properly under maximum output capacity, lowest gauge variation (low film thickness variation), bubble stability, glossy, neat film rolled up as well as durable and long life purposes. All sorts of blown films such as HDPE / LDPE / LLDPE / MDPE / PP / PVC / PA / PLA, mono / multi-layer up to 7 layers are included in our production filed.

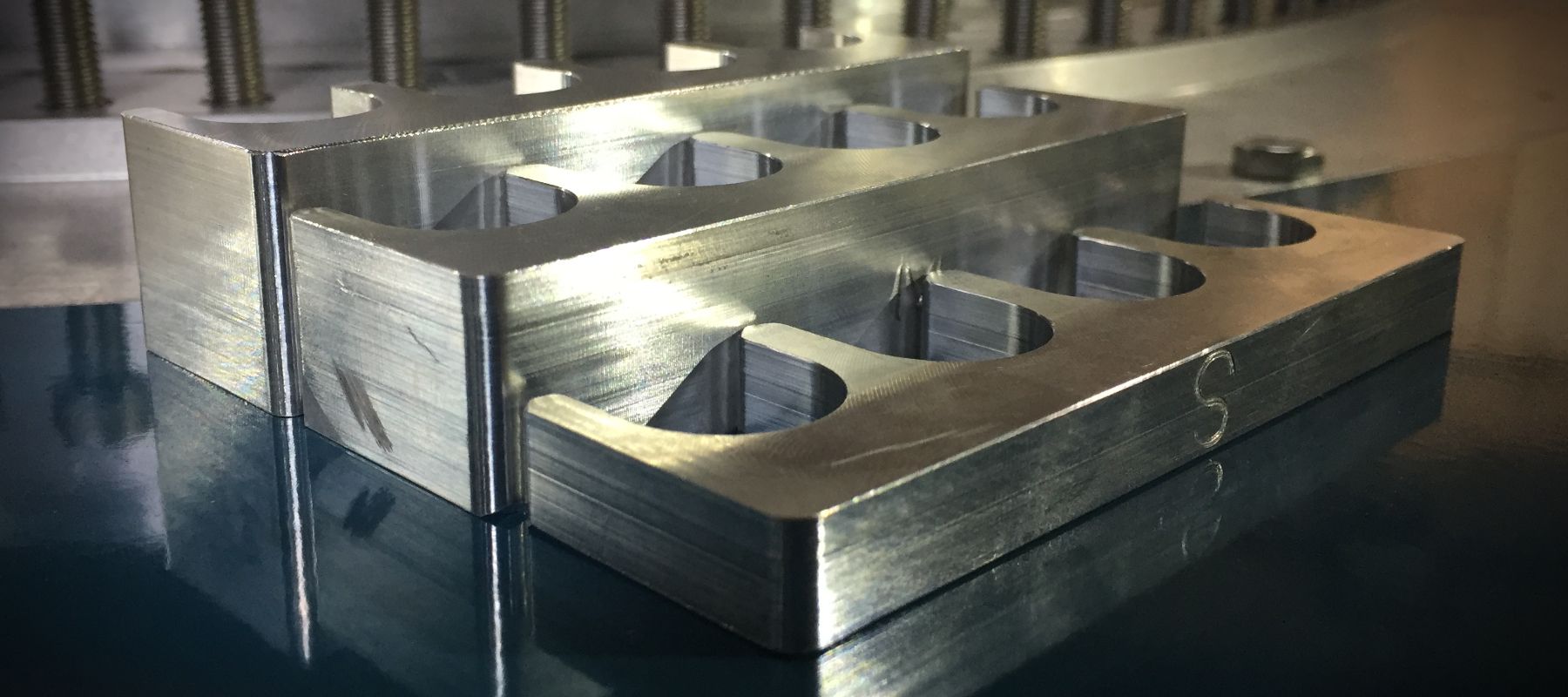

OEM Automatic air ring housings and parts

Backed up by extensive foundry experience, Chuo Yii is a trust-worthy OEM partner for many leading brands internationally, and producing giant housings for their automatic air rings. By replacing traditional forged aluminum and costly processes with high-quality sand casting, it significantly reduced production costs—without compromising on precision, surface quality, or durability. The advanced craftsmanship delivers both performance and value.

ECO Mulch Film Total Solution

In September 2024, Chuo Yii launched a dedicated department to promote ECO-friendly agricultural practices, focusing on two core products: oxo-biodegradable additives (Masterbatch SCM-3611) for mulch film production and microbial fertilizer (SZY) designed for lands covered with mulch films. The CY ECO Mulch Film Solution integrates advanced technologies such as CY Air Ring and Die Head systems, SCM-3611 additives, and SZY fertilizer to provide a comprehensive and sustainable approach to agriculture. Mulch films produced with oxo-biodegradable additives naturally decompose without leaving harmful residues, eliminating labor-intensive removal processes, while the solution supports every stage of farming through expert consultation and application guidance to ensure optimal soil health and crop growth. By reducing water evaporation, retaining moisture, and controlling weeds, this solution enhances productivity and protects the environment. Through workshops and partnerships, Chuo Yii further promotes sustainable farming practices, enabling farmers to achieve higher yields and contribute to a greener and more sustainable future for agriculture.

History Records

- 1997: Chuo Yii Industries was established and acted as mainly machining shop for air ring and all sorts of machining parts.

- 2009: Upgrade the company scale as Chuo Yii Enterprise Co. and at the same time inviting Aluminum Sand casting foundry and brought in vertical CNC machine for huge size air ring processing; as well as the other accessories processing of casting parts.

- 2010: Established the 2nd factory located at the An-Ding Industrial Area, Tainan, where mainly working for aluminum foundry and accepts all sorts of OEM / ODM sand casting works.

- 2024: Established a new department focused on delivering a comprehensive ECO Mulch Film Total Solution. This solution encompasses three key components: Mulch Film Air Ring and Die Head technology, oxo-biodegradable additives, and organic fertilizers.

- Showcase Video